Features

● Reduced vibrations, less elongation and an excellent behaviour under heavy load conditions.

● Extremely flexible, capable to work on small pulley diameters and serpentine drives.

● Strong tensile cords carry high horsepower loads without stretching.

● Flexible, oil and heat resistant backing extend belt life.

● Temperature range: -35°C to +120°C

Applications

Treadmill, Exercise Bikes.

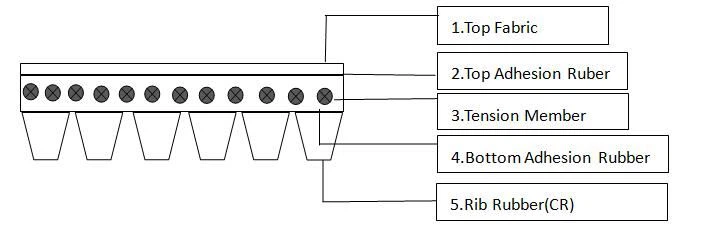

Production Details

Section | PJ |

Rib Pitch(mm) | 2.34 |

Height(mm) | 3.42 |

Degree | 40±1 |

Length Range(inch) | 9~69 |

FAQ

Q1. Why the belt detached from the belt pulley?

The belt tension is too small.

The belt pulley has poor alignment.

Foreign matter embedded in the belt wedge

Q2. How does the noise come about?

Skidding makes noise.

There is rubber powder in the wedge.

Poor alignment of pulley.

The belt touched the edge

Q3. Why does the belt vibrate?

The center distance of the pulley is large.

The belt tension is too small.

The length of multi v belt is not consistent.

Tips

If your drive belt is too loose, it will slip on the front roller pulley or the motor pulley. If it is too tight, it will increase your amp draw to the point that you may have an electronics or motor problem. Due to this, it is better to be on the safe side and replace a drive belt rather than risk over tightening it. Additionally, too much tension can cause bearing failure in the motor and the front roller and front roller pulley failure. It is better to err on having the belt a little too tight rather than too loose due to the possibility of injury if the belt slips.